The U.S.

Department of Energy requests that no alterations be made without permission in

any reproduction of this report.

Ozone Treatment for Cooling Towers

New Energy and Water Saving

Technology to Reduce Cooling Tower Operating Costs

Abstract

The use of ozone as a

maintenance treatment for cooling towers has good potential for operation and

maintenance savings in the Federal sector. A small amount of ozone acts as a

powerful biocide that decreases or nearly eliminates the need to remove

quantities of water from the cooling tower in order to decrease the

concentration of organic and mineral solids in the system. Ozone treatment can

also reduce the need for chemical additives added to the cooling tower water.

In a properly installed and

operating system, bacterial counts are reduced, with a subsequent minimization

of the buildup of biofilm on heat exchanger surfaces. The resulting reduction

in energy use, increased cooling tower operating efficiency, and reduced

maintenance effort provide cost savings as well as environmental benefit and

regulatory compliance with respect to discharge of wastewater from blowdown.

Cooling towers associated

with chillers for air-conditioning are good candidates for ozone application.

Ozone may be a corrosion stimulant rather than an inhibitor, and this can be a

factor in some circumstances. Nevertheless, it is easier to combat corrosion in

a clean system than in one that is biologically and mineralogically fouled.

This Federal Technology

Alert (FTA) provides detailed information and procedures that a Federal

energy manager needs to evaluate most cooling tower ozone treatment

applications. The New Technology Demonstration Program (NDTP) technology

selection process and general benefits to the Federal sector are outlined.

Ozone treatment, energy savings, and other benefits are explained. Guidelines

are provided for appropriate application and installation. Two actual case

studies are presented to give the reader a sense of costs and energy savings.

Current manufacturers, technology users, and references for further reading are

included for prospective users who have specific or highly technical questions

not fully addressed in this FTA.

Ozone

is a molecule consisting of three oxygen atoms and is commonly denoted O3.

Under ambient conditions, ozone is very unstable and as a result has a

relatively short half-life of usually less than 10 minutes. Ozone is a powerful

biocide and virus deactivant and will oxidize many organic and inorganic substances.

These properties have made ozone an effective chemical for water treatment for

nearly a century. During the last 20 years, technological improvements have

made smaller-scale, stand-alone commercial ozone generators both economically

feasible and reliable. Using ozone to treat cooling tower water is a relatively

new practice; however, its market share is growing as a result of water and

energy savings and environmental benefits relative to traditional chemical

treatment processes. A typical system for ozone treatment of cooling towers is

shown in Figure 1. Ozone treatment of cooling tower water is not feasible in

all situations and hence traditional chemical treatment of cooling tower water

is the *only alternative.

*Electorcoagulation is the only serious alternative to

ozone treatment for removal of

minerals and water purification . See Ecoloquip Inc., catalogue.

Fig. 1. Typical Cooling

Tower Ozone Generation System

A

cooling tower functions to cool a circulating stream of water (see Figure 2).

The tower acts as a heat exchanger by driving ambient air through falling

water, causing some of the warmed water to evaporate (evaporation gives off

heat--providing cooling), and then circulating cooler water back through

whatever equipment needs cooling (such as a chiller condenser). Typically,

chemicals such as chlorine and chelating agents are added to cooling tower water

to control biological growth (called "biofilm") and inhibit mineral

build-up (called "scale"). The control of biofilm and scale is

essential in maintaining cooling tower heat transfer efficiency. As the water

volume in the tower is reduced through evaporation and drift, the concentration

of these chemicals and their byproducts increases. Cooling towers also pick up

contaminants from the ambient air. To maintain chemical and contaminant

concentrations at a prudent level, water is periodically removed from the

system through a process called "blowdown"or "bleed off".

The blowdown water and the water lost through evaporation and drift are

replaced with fresh "make-up" water (which will also contain minerals

and other impurities).

Fig. 2. Typical Cooling

Tower Operation

Blowdown

water must subsequently be discharged to a local wastewater treatment facility

or discharged onsite to the environment. The blowdown water typically contains

little organic material, and the local wastewater treatment facility will

charge extra sewage fees for accepting the water. These costs can be quite

significant in the overall costs of operating a cooling tower. Discharge of the

blowdown water to the environment onsite is coming under increasing regulation

due to stricter regulation of the contaminants typically found in blowdown

water. Ozone will dissipate quickly and not be found in the blowdown water.

This reduces the overall chemical load found in the discharged water, making it

easier to comply with regulations.

Most

cooling tower ozone treatment systems include the following components: an air

dryer, air compressor, water and oil coalescing filters, particle filter, ozone

injectors, an ozone generator, and a monitoring/control system. Ambient air is

compressed, dried, and then ionized in the generator to produce ozone. Ozone is

typically applied to cooling water through a side stream of the circulating

tower water as is illustrated in Figure 3.

Fig. 3. Process for Ozone

Treatment of Cooling Tower Water

Field

tests have demonstrated that the use of ozone in place of chemical treatment

can reduce the need for blowdown, and, in some cases where make-up water and

ambient air are relatively clean, can eliminate it. As a result, cost savings

accrue from decreased chemical and water use requirements and from a reduction

of wastewater volume. There are also environmental benefits as fewer chlorine

or chlorinated compounds and other chemicals are discharged.

There

is also a belief within the industry (and some evidence) that under certain

conditions ozone acts as a descaling agent. The premise is that ozone oxidizes

the biofilm that serves as a binding agent adhering scale to heat exchange

surfaces. When scale buildup on condenser tubes is reduced, higher heat transfer

rates are achieved. Increasing the condenser heat transfer rate will reduce the

chiller head pressure, which then allows the chiller to operate more

efficiently and consume less energy.

There

is a growing number of manufacturers and distributors of ozone equipment in the

United States, and the use of this technology is encouraged by several major

electric utilities and by electric utility and cooling tower associations. Each

new application of ozone for cooling tower water treatment increases understanding

of its overall effectiveness and its applicability under differing physical

conditions. The technology has had both success and failure.

More

information on the criteria for applicability and the potential for the use of

this technology in the Federal sector is provided below.

Application Domain

It

is estimated that ozone treatment is applied on anywhere from 300 to 1,000

cooling towers in the United States. Most of these towers dissipate heat

generated by commercial heating, ventilating, and air-conditioning (HVAC)

systems and light industrial processes. The total number of cooling towers

requiring chemical treatment in the United States is estimated at between

500,000 and 600,000.

Biological

growth, scaling, and corrosion are the main maintenance concerns with these

cooling towers. Typical treatment involves the application of chemicals such as

chlorine, sulfuric acid, phosphorous, and zinc compounds. Care must be taken in

the storage, use, or discharge of these chemicals. Care must be taken to ensure

that the proper mixes and proportions of chemicals are used, and to determine

the corresponding blowdown rates. Excessive application can increase the

possibility of corrosion and other undesirable impacts. As traditional chemical

water treatments are being restricted because of environmental concerns, ozone

is gaining acceptance as a viable biocide alternative.

Cooling

tower water is continuously exposed to airborne organic materials, and the

buildup of bacteria, algae, fungi, and viruses presents hazards to the tower

system and to the health of humans encountering the water. For example,

Legionnaire's Disease is caused by the bacterium Legionella pneumophila

that frequently thrives in cooling tower environments. High levels of bacteria

can also lead to an increased risk of microbial influenced corrosion. Certain

sulfate-reducing and iron-metabolizing bacteria can destroy iron piping in as

little as 9 months. Moreover, a biofilm coating on heat exchanger surfaces

reduces heat transfer efficiency. Ozone kills bacteria by rupturing their cell

walls, a process to which microorganisms cannot develop immunity. Residual

ozone concentrations greater than or equal to 0.4 mg/L have been shown to

result in a 100% kill in 2 to 3 minutes for Pseudomonas fluorescens (a

biofilm producer) in a biofilm, while residual concentrations of as little as

0.1 mg/L will remove 70-80% of the biofilm in a 3-hour exposure. Studies have

also shown that ozone concentrations less than 0.1 mg/L will reduce the

populations of Legionella pneumophila in cooling tower waters by 80%.

Another

phenomenon requiring treatment in cooling towers is mineral buildup. Minerals

such as calcium and magnesium, which are common dissolved solids in water, are

deposited by two different mechanisms, thermal and biological. As the water in

a tower evaporates, dissolved solids concentrate in the recirculating water.

Biofilms also start to form on the walls and other components of the tower. In

essence, the biofilm acts as an adherent for mineral micro-crystals. Over time,

deposition of organic and inorganic matter increases scale thickness. Ozone can

loosen and remove the scale if the biofilm is present, but if the biofilm is

not present the ozone may be ineffective in removing the scale. Biofilm may not

be the dominant fraction of scale where the temperature of the heat exchanger

is in excess of 135 F. Scale-forming minerals are less soluble at these higher

temperatures and can deposit from solution directly onto pipe walls.

One

operating concern of a cooling tower is the gradual corrosion of various parts

of the tower. Much of the corrosion in cooling towers is associated with

bacteria that create conditions favoring microbiologically induced corrosion.

When adequate quantities of ozone are injected, control of the microbial

population is accomplished. On the other hand, due to its high chemical

oxidation potential, ozone can be quite corrosive. However, because a very

small amount of ozone performs effectively as a biocide, and because of its

very short half-life, the corrosive effects are minimized.

There

is also an observed phenomenon of ozone-treated cooling tower water, wherein

the pH of the system rises above 8.5 and corrosion protection of the cooling

tower components takes place. This phenomenon may also be dependent upon

make-up water characteristics such as alkalinity and hardness, so it does not

release the operator of the cooling tower from the obligation of making regular

corrosion measurements.

Energy and Water Saving

Mechanisms

Scale

and biological deposits reduce the ability of refrigerant condensers and

industrial-process heat-exchangers to transfer heat. By removing and inhibiting

biological deposits and scale more effectively than chemical treatment, ozone

cooling tower water treatment can improve chiller system performance.

Manufacturers claim an average efficiency gain of 10%; case studies range from

no improvement in efficiency to a 20% improvement in chiller performance.

Energy savings should be estimated for each individual application and based on

the actual operating condition of the condenser or heat exchanger and the type

of scale present. Further, any projected electrical savings must be weighed

against energy consumed by ozone generators and auxiliaries, typically 9 kWh to

14 kWh per pound (0.45 kg) of ozone generated.

Water

is lost from a cooling tower in three ways: drift, evaporation, and blowdown.

Drift occurs when the water droplets become entrained in the discharge

airstream and can be controlled through cooling tower design. Evaporation is

from air passing through the cooling water and absorbing heat and mass.

Blowdown is intentional bleed-off (replaced by make-up water) to reduce the

concentration of contaminants.

The

capacity of a cooling tower is typically measured in tons, the rate at which

the tower rejects heat. One ton of cooling is equal to rejecting 12,000 Btu

(British thermal units) per hour (3.5 kW). This heat is released through

evaporation. The rate of evaporative water loss is about 12 gallons (45.4 L)

per minute for every 500 tons (1,750 kW) of cooling tower tonnage. Ozone will

not increase or decrease the rate of evaporation. However, compared to chemical

treatment at the allowable dosages, ozone treatment contributes far less to the

tower's dissolved solids loading in the circulation water and is therefore more

amenable to operation at higher cycles of concentration.

"Cycles

of concentration," "number of cycles," or "concentration

ratio" are some of the terms used to describe the relationship between the

quantity and quality of make-up water and the volume and constituents of the

bleed-off. This concentration ratio can be thought of as an indicator of the

number of times water is used in the cooling tower before it is discharged,

based on a mass balance between dissolved solids entering the system in make-up

water and dissolved solids leaving the system in blowdown. The higher the

cycles of concentration, the lower the blowdown.

Blowdown

water from a cooling tower can be sent to a municipal drain, or it may require

onsite pretreatment prior to disposal to a drain. In some cases, blowdown may

be stored onsite and then retrieved by a disposal service. The savings are a

direct function of the costs associated with these three disposal processes and

the blowdown volume reduction achieved by the ozone system.

If

water and sewer services are purchased from a municipal or public utility,

reducing blowdown and make-up water requirements will trigger a series of

resource and cost savings for those municipal utilities. If the site operates

its own water treatment and wastewater treatment facilities, reducing blowdown

and make-up water requirements will allow the facility to realize these

benefits directly as follows:

- reduced

pumping power to extract water from source wells or reservoir and pump to

water treatment facility

- reduced

chemical, filtration, and maintenance costs associated with treating and

purifying at the water treatment facility

- reduced

pumping power for distributing the water from the water treatment facility

to the end-user

- reduced

pumping power and associated costs to transport wastewater (blowdown) to

the sewage treatment plant

- reduced

chemical and maintenance costs, and reduced pumping power associated with

sewage treatment at the plant

- reduced

costs associated with permits allowing the discharge of treated sewer

water to a river or stream.

Other Benefits

Besides

its potential to reduce water and energy requirements, ozone treatment can

reduce or eliminate chemical use, eliminate infectious bacteria, and improve

regulatory compliance. Environmental and health benefits occur as potentially

harmful molecules are broken down into less toxic byproducts. Properly

controlled ozone applications decrease the levels of both bacterial and mineral

substances in the waters discharged through blowdown or bleed-off.

Chemical

treatment costs vary according to the size and chemical requirements of the

tower. These costs can be reduced by using ozone as the treatment technology.

Case studies indicate that chemical cost savings are a large contributor to the

cost-effectiveness of an ozone system.

One

manufacturer claims that in normal operation, chiller tubes are usually brushed

out once a year, and the tower sump is shoveled once or twice per year. When

performing a cost savings evaluation for a potential customer, the manufacturer

takes credit for eliminating this maintenance requirement. Although it may not

be necessary to brush out the tubes more than once a year, it may still be

necessary to shovel the sump for a number of possible reasons. Therefore, it is

generally recommended not to accept maintenance and labor savings estimates for

a facility without consulting the facility's maintenance personnel. In

addition, it is more likely that maintenance savings will come from the

reduction in chemical treatment system labor. This savings should be weighed

against maintenance requirements of the ozone system, which are reported to be

minor.

Finally,

with a reduction in biological growth, scale, corrosion, and chemical use, the

issue of liability decreases as well. From a human resources perspective,

reduced risk to personnel health enhances the working environment and makes a

positive public statement.

Variations

Ozone

generation is accomplished by passing a high-voltage alternating current

(6-20kV) across a dielectric discharge gap through which air is injected (see

Figure 4). As air is exposed to the electricity, oxygen molecules disassociate

and form single oxygen atoms, some of which combine with other oxygen molecules

to form ozone. Different manufacturers have their own variations of components

for ozone generators. Two different dielectric configurations exist--flat

plates and concentric tubes. Most generators are installed with the tube

configuration. Cylindrical configurations offer the easiest maintenance.

Fig. 4. Dielectric Process

for Ozone Generation

Mass

transfer of the ozone gas stream to the cooling tower water is usually

accomplished through a venturi in a recirculation line connected to the sump of

the cooling tower where the temperature of the water is the lowest. Since the

solubility of ozone is very temperature-dependent, the point of lowest

temperature provides for the maximum amount of ozone to be introduced in

solution to the tower. Mass transfer equipment can take other forms: column

bubble diffusers, positive pressure injection (U-tube), turbine mixer tank, and

packed tower. The counter-current column-bubble contactor is the most efficient

and cost-effective but is not always useful in a cooling tower setting because

of space constraints. Hence, setups like a venturi followed by an in-line

static mixer, or an eductor followed by an in-line static mixer, are common in

the installation of an ozone system.

Some

ozone treatment equipment vendors propose that the most effective use of ozone

is through controlled low doses proportional to the thermal and organic loads

of the water. Several factors can influence load, or the oxidation reduction

potential (ORP) of the water, including temperature, air quality in the

vicinity of the tower, and cooling demands. To provide a proportional quantity

of ozone, the ORP must be measured frequently and the ozone generation system

must be capable of instant response to changes in ORP. The ORP is a useful

criterion because other biocides can accumulate in the tower when blowdown is

reduced. These biocides include chlorine from the make-up water and bromate

species resulting from the ozone oxidation of trace bromine in the make-up

water.

Unfortunately,

the ORP probe is prone to fouling (usually by a fine layer of calcium

carbonate). Maintenance is simple--and it is essential. If the probe is not

cleaned, the ozone system is likely to stray from proportional control. The

benefit of proportional control and variable ozone generation capability is

that only the necessary quantity of ozone is generated; thus, energy

consumption costs are minimized, as is the possibility of corrosion from

excessive ozone.

Ozone

generators create heat and require a cooling system. Some manufacturers

indicate that water is the coolant of choice; however, others prescribe cabinet

air-conditioning units to keep constant temperatures and reduce air moisture

content. Regardless of which system is employed, reliable cooling is essential

to preserve the dielectric and to optimize ozone generation.

The

potential cost-effective savings achievable by this technology were estimated

as a part of the technology assessment process of the New Technology

Demonstration Program (NTDP).

Technology Screening Process

New

technologies were solicited for NTDP participation through advertisements in

the Commerce Business Daily and trade journals, and through direct

correspondence. Responses were obtained from manufacturers, utilities, trade

associations, research institutes, Federal sites, and other interested parties.

Based on these responses, the technologies were evaluated in terms of potential

Federal-sector energy savings and procurement, installation, and maintenance

costs. They were also categorized as either just coming to market

("unproven" technologies) or as technologies for which field data

already exist ("proven" technologies). Note this solicitation process

is ongoing and as additional suggestions are reviewed, they are evaluated and

become potential NTDP participants.

The

energy savings and market potentials of each candidate technology were evaluated

using a modified version of the Facility Energy Decision Screening (FEDS)

software tool, developed for the Federal Energy Management Program (FEMP),

Construction Engineering Research Laboratories (CERL), and the Naval Facilities

Engineering Service Center (NFESC) by Pacific Northwest National Laboratory

(PNNL) (Dirks and Wrench 1993).

During

the solicitation period in which ozone treatment of cooling tower water was

suggested, 21 of 54 new energy-saving technologies were assessed using the

modified FEDS. Thirty-three were eliminated in the qualitative pre-screening

process for various reasons: not ready for production, not truly energy-saving,

not applicable to a sufficient fraction of existing facilities, or not U.S.

technology. Eighteen of the remaining 21 technologies, including ozone

treatment of cooling tower water, were judged life-cycle cost-effective (at one

or more federal sites) in terms of installation cost, net present value, and

energy savings. In addition, significant environmental savings from use of many

of these technologies are likely through reductions of CO2, NOx

and SO2 emissions. Several of these technologies that have a

demonstrated field performance have been slated for further study through Federal

Technology Alerts.

Laboratory Perspective

Through

laboratory testing, field testing, and theoretical analysis, ozone treatment of

cooling tower water has shown to be technically valid and economically

attractive in many applications. The technology works by virtue of the ability

of ozone to act as a disinfectant and therefore as an alternative to

traditional chemical treatment. Performance of the technology, when properly

applied, has been demonstrated effective. However, like most traditional

chemical treatment programs, ozone is not a cure-all. Ozone is a potential

alternative to traditional chemical treatment methods. More information is

needed on the effectiveness, efficiency and potential other impacts of ozone.

The remaining barriers to implementation involve user acceptance and correct

application. This Technology Alert is intended to address these concerns

by reporting on the collective experience of ozone users and evaluators and by

providing application guidance for Federal-sector installations.

This

section addresses technical aspects of applying ozone treatment technology to

cooling towers. The most appropriate applications are discussed.

Application Screening

To

determine whether ozone is an effective alternative for treating the water in a

specific cooling tower, a technical feasibility screening study and economic

(life-cycle cost) analysis should be performed. In general, cooling towers

associated with chillers for commercial HVAC and light industrial process

cooling are good candidates. Manufacturers claim to have treated both wooden

and metal towers in sizes ranging from 60 to 10,000 tons (210 kW to 35,000 kW).

A list of manufacturers is provided later in this Technology Alert.

Ozone

is not a corrosion inhibitor; however, the higher concentration ratios

resulting from the reduced blowdown volumes raise the pH of the recirculating

water, which helps protect the system from corrosion. This same pH condition

will promote the precipitation of silicates and calcium carbonate if sufficient

pretreatment of make-up water is not provided. Lower pH will remove the scale

but will also increase the corrosion rate from the ozone. For this reason,

make-up water must be of sufficient quality to avoid these problems.

The

strong oxidation potential of ozone is what makes it most attractive for use as

a biocide in water systems. However, this same property also makes it difficult

to use ozone when there is a large chemical oxygen demand (COD) present (this

will consume available ozone) in the water or if local air conditions bring in

large quantities of organics to the tower. The latter condition is the reason

it is not possible to implement ozone water treatment in towers within chemical

plants or at oil refineries. In addition, ozone is corrosive to some materials

such as rubber fittings, gaskets, and certain kinds of metals and alloys. If

these materials are present in a cooling tower, they should be replaced before

ozone system installation if it is practical and economical to do so.

Once

ozone is in the liquid phase, it will last only a short period of time; thus,

maintaining an ozone residual for more than approximately 10 minutes can be

difficult. This limits the application of ozonation in large cooling towers. In

large towers with 100,000 or more gallons, multiple injection points may be

necessary.

Make-up

water that is high in mineral content or dissolved solids may not be conducive

to effective treatment; testing should take place before a system is installed

and on a periodic basis during operation. A side-stream filter may be required

on cooling towers operating with make-up water quality in excess of 150 ppm

calcium hardness. In cases where hardness is in excess of 500 ppm as CaCO3,

or sulfates >100 ppm, ozone can be eliminated as a viable cooling tower

water treatment. A "Cooling Tower Worksheet" is provided in Appendix

A and can be used to characterize the quality of make-up water.

The

U.S. Occupation Safety and Health Administration (OSHA) has established an

ozone exposure limit of 0.1 ppm in air over an 8-hour shift. This could be a

problem if the cooling towers are located on the ground level and are

excessively treated with ozone so that the tower is operating as an ozone gas

stripper (gives off ozone into the air).

Ozone

produces oxidation by-products. There are several secondary products that must

be accounted for in the set-up of cooling tower ozonation. Both iron and

manganese will be oxidized by the ozone to form insoluble particulates that

collect in basins, on screens, or in any scale that is forming. Excessive

amounts of either of these two chemicals in the make-up water will require

pretreatment. In addition, organic compounds that may either be in the make-up

water or introduced through the atmosphere will react with ozone to form

ketones, aldehydes, and amines. If bromide is present, ozone can convert

bromide to hypobromous acid and hypobromite ion. These two species are known

biocides and would be considered helpful in controlling biofilms but

potentially detrimental in the discharge of blowdown. Excessive ozone can

further oxidize the hypobromite ion to bromate, reducing the effectiveness of

these components as biocides.

What to Avoid

Ozone

treatment failures are usually related to an inadequate quantity of

applied/dissolved ozone which can be caused by excessive organic material in

the water or high operating temperature. Therefore, ozone treatment should be

avoided in the following situations:

- high organic

loading from air, water, or industrial processes that would require a high

COD (the ozone will oxidize the organics and insufficient residual may

remain for the water treatment)

- water

temperatures that exceed 110 F (43.3 C) (high temperatures decrease ozone

residence time and reduce overall effectiveness of the ozone treatment)

- make-up

water is hard (>500 mg/L as CaCO3) or dirty make-up water

(softening and/or prefiltering make-up water is sometimes recommended)

- long piping

systems which may require long residence time to get complete ozone

coverage (insufficient ozone residence time may result in incomplete

coverage)

Water

temperature is critical to the success or failure of a system. Above 110 F

(43.3 C) the solubility of ozone is effectively zero for all concentrations of

ozone in the feed gas. Even at 104 F (40 C) the solubility is very small (<3

mg/L). Although some operational data suggest that ozone may be used at

temperatures of up to 135 F (57.2 C), most sources agree that ozone works best

in bulk water temperatures under 104°F (40°C), preferably even below 100°F

(37.7°C). Many comfort cooling systems commonly operate at between 85°F and

95°F (29.4°C and 35.0°C). As temperatures rise, the ozone will dissipate too

fast and not dissolve into the water. This is one reason ozone is not

appropriate for cooling tower systems such as nuclear and fossil generating

plants and absorption refrigerant plants, where temperatures are generally

high.

Problems

can and do occur in the field. The following precautions are not always covered

in manufacturers' instructions but are recommended to be taken during

installation:

- Preparation

of the inlet air is very important for the efficient operation of an ozone

unit as well as for the longevity of the unit. The preparation of the gas

includes removal of dust (particle sizes >1ตm),

moisture (dewpoint <-76° F (-60°C)="99.98%" moisture

removed), and oil. This requires that the pretreatment system be checked

periodically by properly trained personnel and that the appropriate

monitoring equipment for the pretreatment process is installed.

- Make-up

water should be free from noticeable sediment, mud, and discoloration and

should not have extremely high levels of sulfates (<100 ppm) or

hardness (<500 ppm as CaCO3). These values may be determined

by having the water tested by a qualified lab.

- Material in

the ozone-treated system should be compatible with ozone. The ozone

distribution line from the generator to the gas/water contactor carries

the highest concentration (1 to 4% by weight of ozone); therefore, the

line material should be constructed of stainless steel or PVC.

- For

efficient operation, the ozone generator should be located in an

air-conditioned area. Excessive heat (greater than 90 F) could damage the

system or reduce generation capacity.

- The actual

capacity of the ozone generator should be certified by the manufacturer

and checked yearly by the ozone vendor or a qualified maintenance

contractor.

- Corrosion

coupons for copper and steel should be placed in the system and checked at

least every 6 months.

Normally

the cooling tower manufacturer or vendor furnishes operating and maintenance

manuals and training. Manufacturers' instructions should continue to be

followed after the system is installed.

Quantitative Measurements

Ozone

concentration in the water can be measured. The measurement of ozone concentration

has been a source of some debate in the past. Two measurement methods are in

use today that are fairly well accepted. These are Absorption of UV light as

determined by the Beer-Lambert Absorption Law (OREC) and the Indigo method 8311

of HACH Company. The UV absorption method is useful for on-line monitoring of

the ozone concentrations in systems for cooling tower water treatment.

A

useful indicator of scaling is proposed by Pryor and Buffum, called Practical

Ozone Scaling Index (POSI). This index is a correlation for traditional scaling

indices for use in ozone treated systems. Tierney, Feeney, and Mott propose

examining the solubility based on activity coefficients as a function of ionic

strength using the DeBye-Huckel equation. This latter approach is a direct

assessment of scaling under super saturated conditions.

Equipment Integration

The

ozone systems for cooling tower application on the market today are typically

modular and fully self-contained systems with an independent circulation system

for sidestream installation. Ozonators operate from line voltage of 120 volts

single-phase, 230 volts single- and three-phase, and 440 volts single- and

three-phase, at 60 Hz. The higher the output, the more desirable it is to

operate from a higher voltage and multi-phase source. Electric service breakers

are system-mounted for single-point electrical connection. Units can arrive

completely wired and piped, with all components mounted on structural steel

skids (see Figure 5).

Fig. 5. Ozone System,

Showing Piping and Skids

The

necessary piping (usually PVC) and circulation pumps must be provided to

connect the system to the cooling tower water sump. Sometimes, filters must be

installed to capture mineral deposits that will occur from the ozone treatment.

Installation can typically be completed in one day provided the appropriate

electrical service is in place.

Monitoring

and control packages can include integral alarms. Also, interlocking features

are available so that remote fans, blowers, pumps, solenoid valves, etc. will

be activated upon start up of the ozonator and vice versa.

Different

ozone systems have different dimensions or "footprints." A system

designed to treat a 1,000-ton (3,500-kW) tower may have width-height-depth

system dimensions of 37 x 32 x 55 inches (0.94 x 0.81 x 1.4 meters) to 90 x 60

x 30 inches (2.3 x 1.5 x 0.76 meters). To maximize the use of ozone during its

short half-life, the ozone-containing water should be returned to the sump of

the cooling tower as close as possible to the suction side of the circulation

pumps, to ensure that the maximum amount of oxidant is circulated through the piping

and heat exchangers and that some ozone remains to be returned to the top of

the cooling tower.

Maintenance

As

with any technology, it is important to perform routine maintenance in order to

preserve overall efficiency and effectiveness, as well as to extend equipment

life. Preventive maintenance recommendations are listed in Table 1.

Table 1. Recommended

Preventive Maintenance

|

Frequency

|

Description

|

|

Three months |

Check/change filters |

|

Six months |

Change brushes on powerstat control |

|

Annually |

Check dielectrics |

|

Other |

Check air dryer pre- and post-filter as

specified by air dryer manufacturer |

Warranties

Ozone

technology appears to be a reliable method for cooling tower water treatment.

As with any water treatment process, there are reported successes and failures.

As with most equipment, warranties vary between manufacturers. Although a full

comparison of warranty information cannot be provided in this Technology

Alert, one manufacturer warrants the electrodes in the ozone generator for

three years.

The

reader should inquire into the ozone equipment warranty directly from the ozone

equipment manufacturer or sales representative. In addition, the reader should

inquire into the impact on the chiller and cooling tower equipment warranties

directly from the providers of the chillers and cooling towers. Some ozone

technology providers disclaim any warranty with regard to the use of the ozone

equipment. The actual terms of the warranty are usually set forth in the

specification submittal or documents of sale. The reader is encouraged to

investigate the equipment warranties.

Costs

Costs

for a typical ozone system capable of treating a 1,000-ton (3,500-kW) cooling

tower are estimated to range from $25,000 to $70,000, depending upon

manufacturer and actual system size. $36/ton of cooling may be used to provide

a rough cost estimate for an ozone system. The ozone systems are sized

according to need and range from 10 gr/hour to 3,700 gr/hour with corresponding

prices ranging from $10,000 to $300,000. The wide range in cost is a result of

the fact that the size, and subsequently the cost, of the system depends

heavily upon the operating temperature and operating environment of the tower.

Utility Incentives and Support

Although

no utilities currently offer rebates for ozonation, a number have sponsored

seminars and disseminated information. Some have sponsored field tests and

comprehensive studies. The reader is urged to contact your local utility to see

if any energy savings rebates are available.

Texas

Utilities (TU) has worked with one company since spring of 1994 and has

completed four ozone installations for TU customers. Southern California Edison

has studied installations and offers information to its customers. Pacific Gas

& Electric evaluated a test installation over a two-year period and

concluded that ozone was "superior to the current, conventional,

multi-chemical treatment program." Georgia Power, Alabama Power, and the

TVA all sponsored onsite seminars on cooling tower ozonation for their

customers in 1994.

A

large number of case studies have been reported by manufacturers and others.

Observations of field performance, obtained from Federal- and private-sector

analysts and users, are summarized below.

Pacific

Gas and Electric reported effective use of ozone as a biocide following a

2-year study of treatment of mechanical draft counterflow water cooling towers

at a large gas production utility site.

An

Electric Power Research Institute (EPRI) case study focuses on the Digital

Equipment Corporation offices in Littleton, Massachusetts, a 500,000

square-foot complex. The ozonation system was commissioned in 1989. Digital

engineers found ozonation to be economically and environmentally superior to

previous chemical treatments. In addition to the biocidal effect, ozonation

reduced blowdown and eliminated the need for employees to handle chemicals.

Tests over 2.5 years showed no scale formation; corrosion rates were within

industry standards and equipment manufacturer recommendations. Operating costs

were reduced by almost $90,000 per year, and the payback period for capital

investment was only about 2 years.

In

1984-85, NASA performed an experiment in which a 600-ton cooling tower was

retrofitted with an "Ozone-Air HF-90" solid-state ozone generator,

which used 60% less electricity to make a pound of ozone than a conventional

transformer/glass-electrode generator (6.1 vs. 15.3 kWh/lb ozone). The

generator cost a total of $16,057 for a 2-cfm air compressor, air dryer, and

ozone generator. Its use decreased the cooling tower's bacterial count by four

orders-of-magnitude and turbidity by eightfold. Scale accumulations on the

tower loosened and fell off. The effect on chiller energy consumption was not

measured, but the condensers were found to be clean and looking as though they

were newly retubed. Negative impacts included ozone attack on galvanized steel,

copper, and nylon fittings; these were eventually replaced with PVC and

stainless steel.

This

case study examines a system of four ceramic-filled concrete cooling towers

with a capacity of 2,500 tons (8,750 kW) each. The towers reject heat from the

air-conditioning system that provides temperature and humidity control for

Space Shuttle processing in the Vehicle Assembly Building (VAB) at NASA's

Kennedy Space Center (KSC), Florida.

Facility Description

The

cooling towers that provide service to the VAB are located in the Utility Annex

(central plant) at KSC. The make-up water is purchased from a Privately Owned

Treatment Works (POTW) at a cost of $1.18/1,000 gallons ($0.31/1,000 liters)

and blowdown was discharged to local surface waters. Chemical treatment for the

cooling tower was $10.18/ton per year ($2.91/kW) and consisted of two phase

scale and corrosion inhibitors and alternating biocide application. In 1990,

the Florida Administrative Code (FAC) 17-302, Surface Water Quality Standards,

introduced stricter environmental regulations that made the blowdown water

unable to meet regulatory criteria for discharge to the local surface waters.

Hence, ozone treatment was installed in February 1994 in an attempt to reduce

the amount of blowdown being discharged.

Existing Technology Description

The

four cooling towers have a total capacity of 10,000 tons (35,000 kW) and

contain a total of 204,000 gallons (772,000 liters) of cooling water. The

towers had an average make-up water volumetric rate of 146,000 gal/day (553,000

liters/day). Blowdown averaged 67,200 gal/day (254,500 liters/day) with the

rest being a combination of drift and evaporation. The towers reportedly were

operated with a concentration ratio in the range of 4 to 7. Cooling water is

circulated at 7,500 gal/min (28,400 liters/minute) through each tower. The

tower water temperature drops from 110 F (43.3 C) to 90 F (32.2 C).

Ozone Equipment Selection

Ozone

vendors have well-developed specifications for the implementation of

ozone-producing equipment. These criteria consider all aspects of the system.

Many factors must go into the decision to use ozone as a cooling tower water

treatment. Among these factors are the operating environment, operating

temperature, material resistance to ozone, and condition of the make-up water.

However, it is important to have an estimate of the size and cost of an ozone

system before contacting a vendor.

The

size, cost, and operating conditions of the existing system should be obtained

so that a comparison can be made with using ozone. If this information is not

available, the inputs needed may be estimated in the Cooling Tower Worksheet.

It is necessary to know the nominal rating of the cooling tower(s) under

examination. Cooling tower capacity is usually expressed in terms of tons. Once

the tower capacity is obtained, the system can be sized using the equations

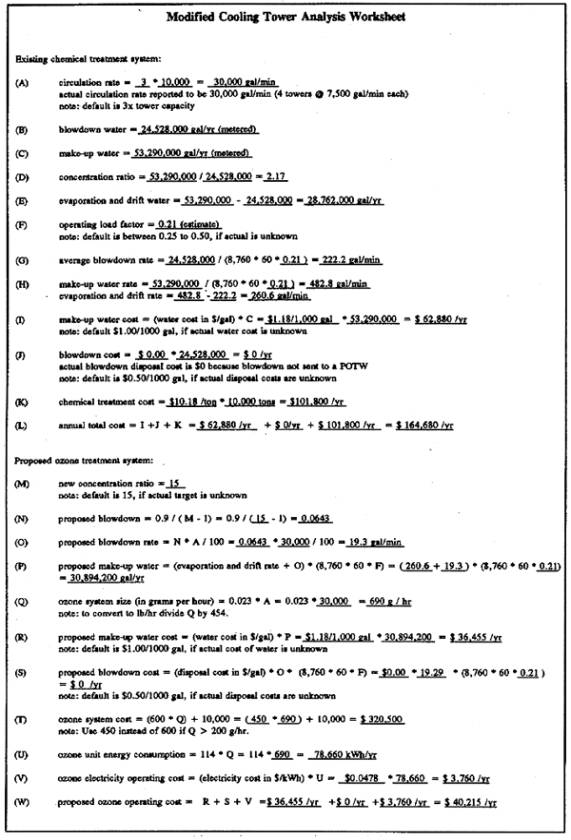

identified in the Cooling Tower Worksheet, as shown in Figure 6.

Savings Potential

A

preliminary analysis will provide estimates that will be useful in making a

decision to implement ozone as a treatment for cooling tower water. The

estimation of the size and cost of an ozone system can be done at several

levels of detail. The highest level of estimation is based on an average

installed cost of an ozone system based on the nominal tonnage of the tower. An

installed cost of $10/kW ($36/ton) is typical for smaller systems. As the ozone

generators get larger, the cost per ton can drop. An average chemical treatment

program cost is $10/ton per year while an average ozone treatment will cost

around $2/ton per year. The cost of make-up water and disposal of blowdown can

vary widely and should be obtained for the particular cooling tower application

under consideration. In addition, local energy costs should be used for the

ozone energy consumption. The estimated costs and savings for the Utility Annex

cooling tower system are listed in Table 2.

Table 2. Estimated Cooling

Tower System Operating Information

|

|

Existing

system |

Ozone

system |

Difference

|

|

Operating cost |

$ 164,680/yr |

$ 40,215/yr |

$ 124,465/yr |

|

Ozone equipment cost |

not applicable |

$ 320,500 |

($320,500) |

|

Annual water use |

59,130,000 gal |

30,894,200 gal |

28,235,800 gal |

Life-Cycle Cost

The

estimates from the above calculations are to use a 690 gr/hr ozone generator.

Annual savings are estimated to be $124,465. Using the Building Life-Cycle Cost

software (BLCC 4.20-1995) available from the National Institute of Standards

and Technology (NIST), the total life-cycle cost for the ozone technology is $663,850

compared to a life-cycle cost of $1,463,555 for the conventional chemical

treatment program. A life cycle of 10 years was used in this analysis. The

comparison report from the BLCC software is illustrated in Figure 7. The

resulting net present value (NPV) is determined to be $799,705 and the

savings-to-investment ratio (SIR) is 3.5. More information on Federal

life-cycle costing and the BLCC software can be found in Appendix B.

Fig.

7. Building Life-Cycle Cost (BLCC)

Fig.

7. Building Life-Cycle Cost (BLCC)

Implementation and Post-Implementation

Experience

The

ozone system installed at the Utility Annex has a generation capacity of 600

gr/hr. For comparative purposes, the actual costs and savings reported by

Tierney and Mott are identified in Table 3. The overall savings was determined

to be $100,012/year. Experience at the Utility Annex cooling towers has shown

that ozone treatment is indeed a viable water treatment method for cooling

towers. The idea that zero blowdown can be practiced is not feasible, since the

calcium levels will eventually get too high and scale will form. At 60 to 80

cycles, the cooling towers were 60% plugged with scale in 8 months. In

addition, the ozone injection circuit was plagued by the same problem and was

difficult to keep on line. This forced the operators to reduce the

concentration cycles between 10 and 20. Research indicated that they could

increase the concentration cycles between 30 and 40, which is where they are

now.

Table 3. Reported(a)

Cooling Tower Operating Information

|

|

Existing

system |

Ozone

system |

|

Operating cost

|

$ 161,484/yr |

$ 61,472/yr |

|

Ozone equipment cost |

not applicable |

$ 330,000 |

|

Annual water use |

53,290,000 gal |

35,690,000 gal |

|

(a) Reported from telephone interview with

site personnel. |

||

The

ozone generator failed several times due to excessive heat but was covered by

the manufacturer's warranty. To remedy the failure conditions of the ozone

unit, an air-conditioned enclosure was built to remove some of the cooling load

on the ozone generator's cooling system. This points out the need to have the

cooling system for the ozone generator serviced regularly to reduce failures in

the unit and to consider the cost of enclosing and cooling the unit if it must

operate in a high temperature environment.

Ozone

injection systems are susceptible to scale build-up due to the dry ozone/air

stream coming into contact with the mineral-saturated cooling tower water. This

problem was solved by injecting potable water (which is not mineral-saturated)

at the site of ozone injection.

Overall,

the results are good. The reduction in blowdown, make-up water, and chemical

costs usually will provide a simple payback time of less than six years.

This

case study concerns a system of two cooling towers with a capacity of 300 tons

each, located at the Lockheed Martin Electronics and Missiles Ocala Operation

in Ocala, Florida. Data were taken from a paper written and presented at the

DOE Pollution Prevention Conference XI in Knoxville, Tennessee, on May 16, 1995

(See "Who Is Using the Technology" for a contact at Lockheed Martin).

The

Lockheed Martin Electronics and Missiles Ocala Operation is responsible for the

production of electronic assemblies, printed circuit boards, and wiring

harnesses for space exploration, defense weapon systems, and defense

communication systems. The cooling towers support a variety of test and

production equipment and also support secondary cooling of HVAC systems.

The

cooling tower system consists of two conventional Marley counterflow cooling

towers with an operating capacity of 500 gallons each. The towers operate with

an influent water temperature of 85 F (29.4 C) and an effluent temperature of

approximately 75 F (23.8 C), for an overall temperature drop of 10 F (5.6 C).

The facility was not connected to a public works wastewater treatment facility,

so the blowdown water had to be transported offsite for disposal, at an annual

cost of $45,360.

The

cooling towers had an annual make-up water volume of 2.482 million gallons.

Since the installation was not connected to an outside water source, the source

of make-up water was treated wastewater recycled from the manufacturing

process. This make-up water had a total organic carbon (TOC) content that was

greater than 1500 ppm. This high TOC concentration resulted in a large chemical

demand in treating the cooling tower water, which was reflected in the overall

chemical treatment costs. The water was soft (~=50 ppm as CaCO3) and

contained ferrous sulfate from the manufacturing process. Poor system control

resulted in either excessive chemical use or insufficient chemical feed, with

subsequent scale formation requiring acid cleaning. The tower required acid

cleans several times a year and the chiller condensers were cleaned at least

twice during the summer months due to biofilm growth that resulted in excessive

pressure head.

The

existing multi-chemical treatment program consisted of the application of

chlorine gas, additional biocides, and corrosion inhibitors. The total annual

chemical costs were $24,733.

The

savings data identified in Table 4 were generated by personnel in charge of

system operation. Significant savings were achieved in all elements of the

process: labor, energy, chemical, and blowdown disposal.

Table 4. Operating Cost

Comparison for Cooling Water System Per Year

|

Item

|

Chemical

Treatment |

Ozone

Treatment |

|

Electrical operation |

$0 |

$2,592 |

|

Chemicals |

$18,613 |

$0 |

|

Labor |

$9,360 |

$2,808 |

|

Blowdown hauling |

$45,360 |

$4,536 |

|

Chlorine gas |

$6,120 |

$0 |

|

Power consumption |

$118,715 |

$47,479 |

|

Total cost/year |

$198,168 |

$57,415 |

Savings

with ozone treatment were $140,753/year with an NPV of $1,072,235 and an SIR of

31.9.

In

this situation, prior to the installation of the ozone system, the costs and

maintenance were high enough to cause the facility to examine alternative

methods for cooling tower water treatment. The result was a decision to use

ozone for the treatment of the water. A proposal from REZ-TEK International,

Inc. was obtained in 1993 for the installation. In February 1994, a REZ-TEK

model S-1230 was installed and put into service. The model S-1230 produces 0-30

grams of ozone per hour and sold for around $35,000. The ozone system came

completely self-contained with a foot print of 37 inches by 30 inches and a

height of 55 inches. The appropriate electric service was already in place, so

the installation of the unit took one day. It should be noted that the time and

cost of installation will increase if the appropriate electrical service is not

available.

During

initial start-up of the system, a significant amount of suspended particles

were observed. This was from the precipitation of the minerals in the water and

was an expected phenomenon. In this application, the suspended solids were

removed by application of hydrogen peroxide as a make-up water pretreatment.

Addition of ferrous sulfate was also eliminated from the make-up water, and the

sump water was filtered.

The

bacterial count was reduced three orders-of-magnitude, from one million to one

thousand colony-forming units (CFUs), and blowdown waste was reduced 90%. The

operator reported that no chemicals had been added to the cooling tower one

year after the ozone system was installed.

Labor

savings were reported qualitatively: "Maintenance operator was enabled to

alternate one chiller and remove waste heat from air conditioning and test

chambers. System has allowed the maintenance operator time to focus on the

other facility issues." An important aspect of this type of savings is

that it will free up maintenance staff to address other operation and

maintenance issues at the facility.

Corrosion

tests indicated that copper in the tower neither corroded nor pitted, while

iron showed 2.0 mils per year of corrosion and 0.37 mils per year of pitting.

It was reported that the corrosion effect of ozone was 50% of that of chlorine

treatment.

The

findings of the case study were very positive one year after installation and

start-up.

Much

excitement has been generated around this technology. Manufacturers and vendors

see a huge market; cooling tower operators see the potential costs savings,

environmental benefits, and reductions in maintenance and health hazards. As a

result, many players have appeared in the field along with a variety of

products, services, and performance claims.

With

each installation, more is learned about actual performance, cost, and

benefits. There have been reports of success and of failure. Manufacturers

indicate that many of the failures were due to poor design or inferior quality

ozone-generating equipment. Sometimes the application of ozone was

inappropriate due to the make-up water condition or the tower operating conditions.

In these situations, a traditional chemical treatment program will be more

effective.

There

are many reasons to consider ozone: when chemical costs are high or chemical

management is burdensome, when chemical water treatment is not effective, when

water and sewer charges are high or increasing, or when local regulations

require blowdown to be treated before discharge to surface waters.

Potential

users should carefully review their current and historic costs related to

cooling tower water treatment and the performance of their associated cooling

equipment. The guidance provided in this Technology Alert should help

indicate whether it would be worthwhile to consider the technology.

The

firms listed below were identified as manufacturers and suppliers of the

technology at the time of this report's publication. This listing does not

purport to be complete, to indicate the right to practice the technology, or to

reflect future market conditions.

American Ozone Systems, Inc. 1301 North Elston Avenue

Chicago, IL 60622 (312) 278-3000

Biozone Technologies 7 Old Dock Road

Yaphank, NY 11980 (516) 734-2696 or c/o MW Equipment, Inc.

(212) 643-7700 (attn: Dick Dabberdt)

Capital Controls Company , Inc. 3000 Advance

Lane

PO Box 211 Colmar, PA 18915 (215) 997-4030

Carus Chemical Company Ozone Systems

315 Fifth Street Peru, IL

61354 (815) 223-1500

Clear Water Technology, Inc. 850#E Capitolio

Way

San Luis Obispo, CA 93401 (805) 549-9724

Diversey Water Technologies, Inc. 7145 Pine

Street

Chagrin Falls, OH 44022 (800) 669-0053

EDC 3110 W. Story Rd. Irving, TX 75038

(214) 257-0322 (attn: Patrick Hunt)

Emery-Trailgaz Ozone Company 11501 Goldcoast

Dr. Cincinatti,

OH 45259-1643 (513) 530-7702

Hankin Atlas Ozone Systems, Ltd. 690 Progress

Avenue, Unit #12

Scarborough, Ontario M1H 3A6 Canada (416) 439-7860

Griffin Division of Ozonia North America

PO Box 330, 178 Route 46 Lodi, NJ 07644

(201) 778-2131

Marley Cooling Tower 7401 W. 129th

St. Overland Park, KS 66213

(913) 664-7614 (attn: Terri Robee)

Mitsubishi International Corporation 875

North Michigan Avenue,

Suite 3900, John Hancock Center Chicago, IL 60611

(312) 640-5647

Osmonics, Inc. 5951 Clearwater Drive

Minnetonka,

MN 55343-8990 (612) 933-2277

Ozonair International Corporation

903 Grandview Drive South San Francisco, CA 94080

(415) 952-9904

Ozone Research & Equipment Corp. 4953

West Missouri Ave. Phoenix, AZ 85301

(602) 931-7332

Ozone Technology Inc. 2113 Anthony Dr. Tyler,

TX 75701

(903) 581-2060

Ozonia North America 2924 Emerywood Parkway

PO Box 70145

Richmond, VA 23229

(804) 756-0500

Ozotech, Inc. 2401 Oberlin Rd. Yreka, CA

96097

(916) 842-4189

Ozone Technology Incorporated 2113 Anthony

Dr. Tyler, TX 75701

(903) 581-2060

Panlmatic Company 79 Bond Street Elk Grove

Village, IL 60007

(708) 439-4454

Sumitomo Precision Products Co., Ltd. 345

Park Ave. New York, NY 10154

(212) 826-3634

PCI Ozone & Control Systems, Inc. One

Fairfield Crescent West Caldwell, NJ 07006

(201) 575-7052

REZ-TEK International Corp. 15 Avenue E

Hopkinton, MA 01748

(800) 770-8554 (attn: Jim Daly)

Wheelabrator Engineered Systems, Inc. P.O.

Box 36, 441 Main Street Sturbridge, MA 01566

(508) 347-7344

Zelsman and Associates 329 Nebraska Ave.

Longwood, FL 32750

(407) 831-6268 (attn: Jack Zelsman)

The

list below is a partial list of Federal-sector contacts, agencies, and

locations that already have the new technology installed and operating. Many of

the listed Federal energy managers are knowledgeable about ozone for cooling

tower water treatment. The reader is invited to ask questions and learn more

about the new technology.

Kennedy Space Center (EG&G)

Kennedy Space Center, FL

Dan Tierney (407) 867-1190

Lewisburg Penitentiary

Lewisburg PA

Lou Brememen (717) 523-1251 x418

Lockheed-Martin

Ocala, FL

Arvind Patel (904) 687-5683

Martin-Marietta

Oak Ridge, TN

Terry Copeland (615) 574-1550

McDonnell-Douglas Space System

Kennedy Space Center, FL

Jose Rodriguez (407) 867-5141

NASA Houston

Houston, TX

Mark Watts (713) 666-2828

United States Post Office

Manchester, NH

Ron Bruzenski (603) 644-4071

The

documents listed below were used in the preparation of this Technology Alert

and may be of further use to anyone considering application of cooling tower

ozone treatment. A list of pertinent associations and organizations is also

provided.

User and third party field and lab test

reports and other technical publications:

1994

ASHRAE Handbook, Equipment Volume, Chapter 20, Cooling Towers, American

Society of Heating, Refrigerating, and Air Conditioning Engineers, Inc.

Aqua-Chem,

Inc. nd. "Ozone and the Environment." Aqua-Chem, Inc., Raleigh, North

Carolina.

Burda,

Paul A., Brian A. Healey, and Guna Selvaduray. 1993. "Performance and

Mechanisms of Cooling Tower Treatment by Ozone." Paper No. 488, presented

at Corrosion 93, the NACE Annual Conference and Corrosion Show. Pacific Gas and

Electric Company Technology Center, San Ramon, California.

Coppenger,

G. D., B. R. Crocker, D.E. Wheeler, 1989, Ozone Treatment of Cooling Water:

Results of a Full-Scale Performance Evaluation, Oak Ridge Y-12 Plant,

Martin Marietta Energy Systems, Inc.

Donohue,

J.M. 1972, Cooling Tower Treatment -- Where Do We Stand?, National

Association of Corrosion Engineers.

Dore,

M. 1985. "The Different Mechanisms of the Action of Ozone on Aqueous

Organic Micropollutants." In Proceedings of the International Ozone

Association Conference, London, November 13-14, 1985.

Echols,

Joseph T., and Sherman T. Mayne. 1990. "Cooling Tower Management Using

Ozone Instead of Multichemicals. ASHRAE Journal, June 1990.

Edwards,

H., P.E. Banks. 1987. "Ozone--An Alternate Method of Treating Cooling

Tower Water." Paper No. TP87-17, presented at the 1987 Cooling Tower

Institute Annual Meeting, New Orleans, February 25-27, 1987.

Electric

Power Research Institute (EPRI). 1992. Tech Application: Ozonation of

Cooling Tower Water. No. 3, EPRI Industrial Program - Environment and

Energy Management, Palo Alto, California.

HACH

Company. 1992. Water Analysis Handbook. 2nd Edition. HACH Company,

Loveland, Colorado.

Henley,

Mike. 1994. "Ozone Review: Ozone Finding Small Niche as Cooling Tower

Treatment." In Industrial Water Treatment, March-April 1994.

Kaur,

K., T.R. Bott, and B.S.C. Leadbeater. 1992. "Effect of Ozone on Pseudomonas

Fluorescens." In Biofilms--Science and Technology, L.F. Malo et

al. eds., pp. 589-94. Kluwer Academic Publishers, Netherlands.

Kenney,

Ray. 1983, Ozonation as Cooling Tower Water Treatment: A Pilot Study,

IBM Technical Report TR 20.0430

Legube,

B., J-P. Croue, D.A. Reckhow, M. Dore. 1985. Ozonation of Organic Precursors

Effects of Bicarbonate and Bromide, In Proceedings of the International

Ozone Association Conference, London, November 13-14, 1985

Masschelein,

W.J. 1985. Mass Transfer of Ozone Through Bubbling and Chemical Reactions in

Water, In Proceedings of the International Ozone Association Conference,

London, November 13-14, 1985.

Miltner,

R. J., H. M. Shukairy, R. S. Summers, Disinfection By-Product Formation and

Control by Ozonation and Biotreatment, Journal of American Water Works

Association, V84 n11 pp. 59-62, November 1992.

Montgomery,

James M., Consulting Engineers, Inc. 1985. Water Treatment Principles and

Design. John Wiley & Sons, New York.

Nebel,

Carl. 1985, "The Oxidation Mechanism of the Oxyozonsynthesis

Process," In Proceedings of the International Ozone Association

Conference, London, November 13-14, 1985.

Nebel,

Carl. 1994. "Design Consideration for Ozone Water Treatment Systems in

Cooling Towers." Paper No. TP94-07, presented at the 1994 Cooling Tower

Institute Annual Meeting, Houston, Texas, February 13-16, 1994. PCI Ozone &

Control Systems, Inc.

Nebel,

Carl. 1995, Design of Ozone Systems for Cooling Towers, Engineered

Systems, April 1995.

Ozone,

Kirk-Othmer Encyclopedia of Chemical Technology, Volume 16, Third Edition,

Copyright 1981, John Wiley and Sons, Inc.

Pacific

Gas & Electric (PG&E). 1991. Evaluation of Ozone Technology for

Chemical Treatment Replacement in Cooling Towers (Power Plant Systems): Final

Report. Report 006.2-90.6, Pacific Gas and Electric Company, San Ramon,

California.

Patel,

Arvind B. 1995. Pollution Prevention in Cooling Tower Water Treatment. DOE

Pollution Prevention Conference XI, Knoxville, Tennessee, May 16, 1995.

Pope,

Daniel H., Lawrence W. Eichler, Thomas F. Coates, Jeffrey F. Kramer, and

Reginald J. Soracco. 1984. "The Effect of Ozone on Legionella

pneumophila and Other Bacterial Populations in Cooling Towers." Current

Microbiology 10:89-94.

Pryor,

A.E., T.E. Buffum, "A New Practical Index for Predicting Safe Maximum

Operating Cycles in Ozonated Cooling Towers," Ozone Science &

Engineering, 17, 71-96, 1995.

Puckorius,

Paul R. 1993. "Ozone Use in Cooling Tower Systems - Current Guidelines -

Where It Works." Ozone Science & Engineering 15:81-93.

Stumm,

W., J.J. Morgan, "Aquatic Chemistry." 2nd Ed., John Wiley & Sons,

New York, NY, 1981.

Soeyink,

V.L., D. Jenkins, "Water Chemistry," pp76-79, J. Wiley & Sons,

Inc., New York, NY, 1980.

Tierney,

D.J. Cooling Tower Ozone Treatment at Kennedy Space Center.

EGG-8600/BOC-125 Tierney 407-867-1190.

Tierney,

D.J., R.A. Mott. Ozone V. Chemical Treatment of Cooling Towers at Kennedy

Space Center: A Progress Report. Tierney 407-867-1190.

Tierney,

D.J., E.S. Feeney, R.A. Mott. Case History: Performance Evaluation of Ozone

Cooling Water Treatment at Kennedy Space Center. Tierney 407-867-1190.

Wattinger,

Ralph. 1993. "Ozone: An Environmentally Beneficial Means of Treating

Cooling Tower Water." Presented at the 2nd International Energy and

Environmental Congress, Minneapolis, Minnesota, August 4-5, 1993. REZ-TEK

International, Inc., Mountaindale, New York.

Weisstuch,

A., D.A. Carter, C.C. Nathan. 1971, Chelation Compounds as Cooling Water

Corrosion Inhibitors, National Association of Corrosion Engineers.

Utility, Information Service, or Government

Agency Technology Transfer Literature:

City

of San Jose. 1992. Water Conservation Guide for Cooling Towers.

Environmental Services Department, City of San Jose, California.

Electric

Power Research Institute (EPRI). 1992. TechApplication: Ozonation of Cooling

Tower Water. No.3, EPRI Industrial Program--Environmental and Energy

Management.

Electric

Power Research Institute (EPRI). 1992. Ozonation of Cooling Tower Water: An

Alternative Treatment Technology. BR-100426, Electric Power Research

Institute, Palo Alto, California.

International

Ozone Association. 1994. Ozone News 22:5 (1994).

Associations and Professional Organizations:

American Society of Heating, Refrigerating

and Air-Conditioning Engineers, Inc. (ASHRAE)

1791 Tullie Circle, N.E. Atlanta, GA 30329

Cooling Tower Institute P.O. Box 73383

Houston, Texas 77273

Phone: (713) 583-4087 Fax: (713) 537-1721

Electric Power Research Institute (EPRI) 3412

Hillview Avenue P.O. Box 10412 Palo Alto, CA 94303

Phone: (415) 855-2411

International Ozone Association

Pan American Group 31 Strawberry Hill Avenue Stamford, CT 06902

Phone: (203)348-3542 Fax: (203)967-4845

National Association of Corrosion Engineers,

International Products Division

P.O. Box 218340 Houston, Texas 77218

Phone: (713) 492-0535 Fax: (713) 492-8254

General Contacts

Ted Collins

New Technology Demonstration Program

Program Manager

Federal Energy Management Program

U.S. Department of Energy

1000 Independence Avenue, SW, EE-92

Washington, DC 20585

(202) 586-8017

Fax: (202) 586-3000

theodore.collins@hq.doe.gov

Steven A. Parker

Pacific Northwest National

Laboratory

P.O. Box 999, MSIN: K5-08

Richland, Washington 99352

(509) 375-6366

Fax: (509) 375-3614

steven.parker@pnl.gov

Technical

Contact

Steven

A. Parker

Pacific Northwest National Laboratory

P.O. Box 999, MSIN: K5-08

Richland, Washington 99352

(509) 375-6366

Fax: (509) 375-3614

steven.parker@pnl.gov

Produced for the U.S. Department of Energy by the Pacific Northwest National

Laboratory

December 1995